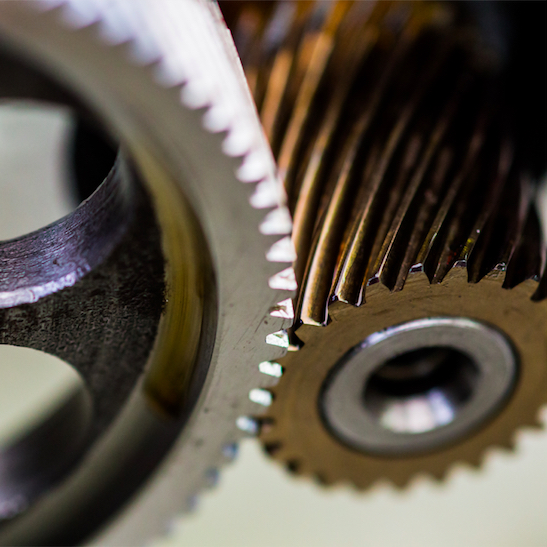

Gear Manufacturing

Motors & Frequency Converters

Brakes

SPECIAL GEARS

customized. cost-efficient. innovative.

In order to fulfill your individual requirement precisely, in our planning, manufacturing and delivery we concentrate on what is essential in special gears manufacturing. We calculate drive engineering explicitly for your application and design a transmission which is able to do exactly what you need – no more, no less!

Through the collaborative compilation of the products requirements document we support you in determining the specific key data like braking torque, loads, speeds, repetition cycle etc. As a reliable and experienced partner MAS supports you in the creation of your customized and cost-efficient quality product, from engineering and gear calculation over prototype manufacturing and all required tests to serial production.

The precise and perfect solution.

STANDARD GEARS

customer-oriented. independent. seamlessly integrated.

On the basis of the specific key data we create a drive concept to help you objectively select the best available standard gear for your application. If necessary we adapt the standard gear to customer specifications and take care of on-site commissioning.

The perfect business solution.

MOTORS & FREQUENCY INVERTERS

powerful. resource-efficient. intelligent.

We provide you with expert advice for the selection of motors and frequency inverters for complex applications where e.g. ambient temperature or performance characteristics are not according to standard. We take aspects like voltage, temperature, insulation class, start torque, frequency inverter operation, external cooling, self-ventilation or without a fan, encapsulated winding (IP67) etc. into consideration.

BRAKES

high quality. reliable. low maintenance.

MAS Engineering is the general distributor for Galvi brakes in Austria and the sales partner for Germany. Galvi has been the leading international expert for service and working brakes since 1962 (www.galvi.com).

Our products in Use

For the electrical dead space regulation for the transport of gas our extra light, free-hanging spur gear copes with heavy drive loads and a wide range of temperatures in outside use:

International manufacturer of compressor technology.

We have delivered more than 16.000 spur gear and worm gear units which move the chamber discharge of a significant number of pellet heating systems: Ökofen.

We supply the paper industry with special transmissions for ambient temperatures of up to 130 °C or for use in wet surroundings with IP67: international manufacturer for scrapers for paper-making machines.

We produce spindle gears for specialized industrial use like for the heavy weight loads of winding stations for transformers (international manufacturer of transformers with a part weight of up to 300t) and for the high temperatures of continuous casting plants (international manufacturer of continuous casting plants for steel production).