Project ‘New life for spindle lifting elements’

Customer Information

Company Primetals Technologies (formerly Siemens VAI – ‚Voest’)

Sector Systems engineering * steel production

Location Linz, Austria; London, UK & other locations around the world

Employees > 7.000 employees worldwide

Project start 2007 – ongoing

Project Description

Initial Situation

Initial Situation

Siemens VAI, nowadays known as Primetals Technologies, contacted MAS Engineering because they had problems with a manufacturer who had provided spare parts for continuous casting plants and were thus looking for an alternative supplier. The request was to re-engineer a small series of lifting elements for the lateral adjustment of ingot molds, which had been in use since 1978, and to store them in order to ensure short-term supply capability for the global customer base.

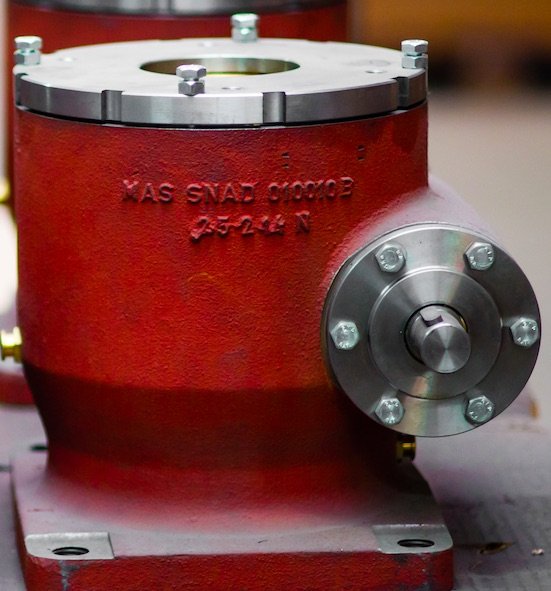

These technical details make this component exceptional:

- Exceptional gradient of the trapezoidal thread spindle (Tr60x6)

- Material ETG100

- ‚spun‘ spindle to ensure gradient tolerance (maximum slope error of 0,1 mm over a length of 300 mm)

- divided spindle nut for a zero-backlash spindle (max. 0,1 mm)

- Spindle-play tolerance can be adjusted to wear during operation

- Spindle deviation of 2° on the xy-axis

The situation is complicated by the fact that it is impossible to calculate the number of spare parts required and that the demand is subject to strong fluctuation (from 0 to 80 transmissions per year).

Solution

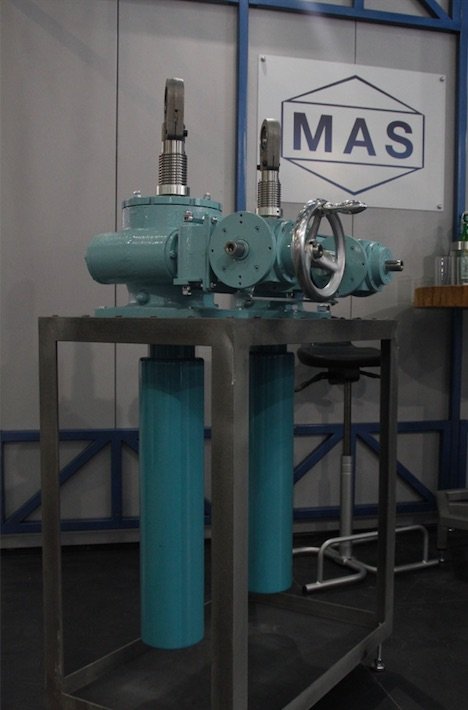

The smooth handling of the order led to the set-up of an ongoing framework contract with the stockpiling of 4 sets à 4 transmissions, which helps us to achieve higher production numbers and leads to moderate prices in the spare part segment.

Highlights

Due to excellent collaboration with the technical department of Siemens VAI we were able to successfully re-engineer the spindle lifting elements within 6 months, including prototyping. Meanwhile, our spare parts are in use in continuous casting plants all around the world, e.g. in Linz/Austria, Lipezk/Russia, Belgrade/Serbia, Santa Cruz/Brasil etc.

Customer Statement

Due to the problems with our original spare part manufacturer we were forced to look for alternatives. We found a competent and reliable partner in MAS. The sheer courage to accept this order amazed me to such a degree that I have supported this endeavor on the part of VAI from the beginning. MAS convinced our engineers in all quality audits with the high quality of their components and of the assembly test sequences. Moreover, ever since the change of our suppliers the geographical proximity to MAS as well as their flexibility has facilitated customer approval and quality testing, as we are now able to do this quickly and easily on site.

The Chief Engineer of the Spare Parts Department, Siemens VAI